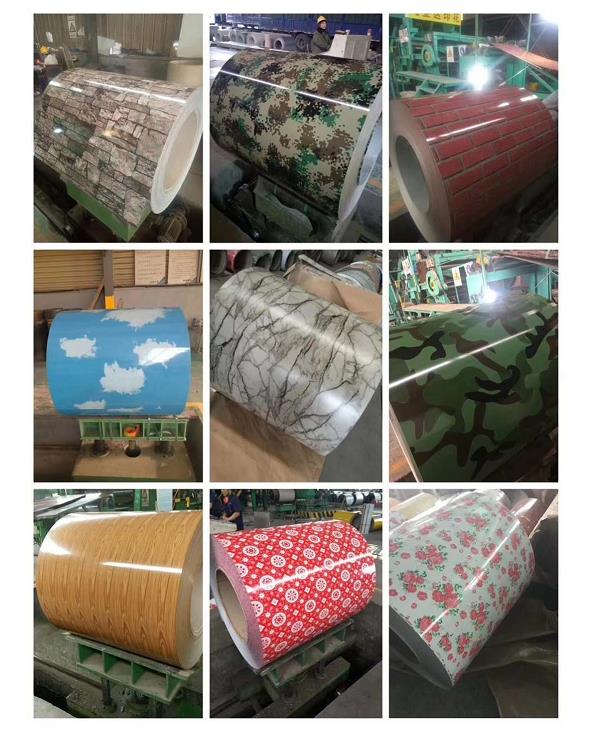

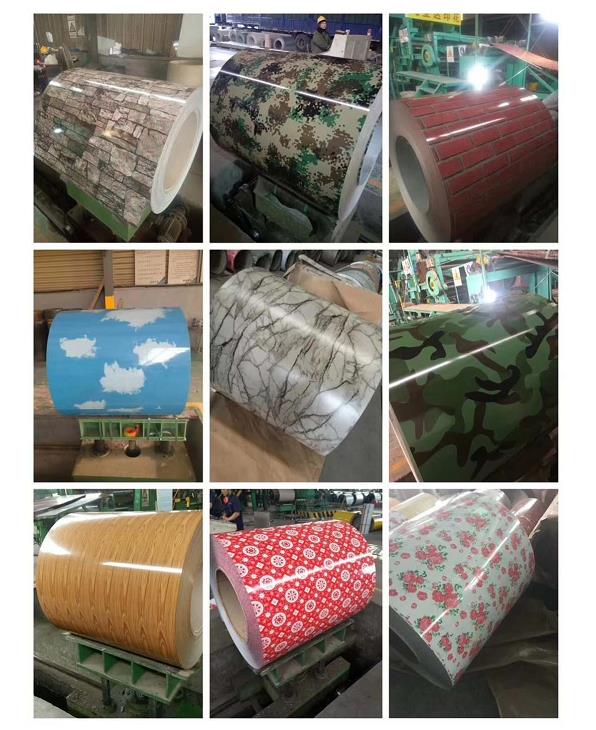

PPGL Color Coated Steel Coil

Product Name: PPGI/PPGL Color Coated Steel Coil

Standard: EN, DIN, JIS, ASTM

Thickness: 0.12-6.00mm (±0.001mm); or customized as required

Width: 600-1500mm (±0.06mm); or customized as required

Zinc Coating: 30-275g/m2, or customized as required

Substrate Type: Hot dip galvanized steel, Hot dip galvalume steel, Electro galvanized steel

Surface Color: RAL series, wood grain, stone grain, matte grain, camouflage grain, marble grain, flower grain, etc

PPGI, also known as pre-coated steel, coil coated steel, and colour coated steel, stands for Pre-Painted Galvanised Iron. Galvanized Iron is obtained when coated steel is continuously hot dipped to form Zinc of purity greater than 99%. The galvanized coating provides cathodic and barrier protection to the base steel. PPGI is made by painting of Galvanized Iron prior to formation as it significantly reduces corrosion rate of zinc. Such a corrosion protection system makes PPGI attractive for structures designed to last a long time in aggressive atmospheres.

Product | |

Material | DC51D+Z, DC52D+Z, DC53D+Z, DC54D+Z |

Zinc | 30-275g/m2 |

Width | 600-1250 mm |

Color | All RAL Colors, or according to customers require. |

Primer Coating | Epoxy, Polyester, Acrylic, Polyurethane |

Top Painting | PE, PVDF, SMP, Acrylic, PVC, etc |

Back Coating | PE or Epoxy |

Coating Thickness | Top: 15-30um, Back: 5-10um |

Surface Treatment | Matt, High Gloss, Color with two sides, Wrinkle, Wooden color, Marble |

Pencil Hardness | >2H |

Coil ID | 508/610mm |

Coil weight | 3-8tons |

Glossy | 30%-90% |

Hardness | soft (normal), hard, full hard(G300-G550) |

HS Code | 721070 |

Country of Origin | China |

Pre-painted galvanized steel coil can be further processed into plain, profile, and corrugated sheets, which can be used in many areas, for example:

1. Construction industry, such as roofing, interior, and exterior wall panel, the surface sheet of the balcony, ceiling, partitioning walls, windows, and door panels, etc. The PPGI steel is durable and wear-resistant and it will not be deformed easily. So it is also widely used in the renovation of buildings.

2. Transportation, for example, decorative panels of the car, deck of train or ship, containers, etc.

3. Electrical equipment, mainly used to make shells of the freezer, washing machine, air conditioner, etc. The PPGI coils for home appliances are of the best quality, and the production requirements are the highest.

4. Furniture, like wardrobe, locker, radiator, lampshade, table, bed, bookcase, shelf, etc.

5. Other industries, such as roller shutters, advertising boards, traffic signboards, elevators, whiteboards, etc.

Package:

Packing Details: Bundle with steel strip, shipped in wooden cases or wooden pallets

Delivery Details: Use trays to facilitate loading and unloading

Standard Export Seaworthy Package.

Or Package can also according to your requirements

Leading Time:

Within 7-10 days after receipt of advance payment

Application:

|

|

|

|

|

|

Our Service :

Prompt reply: We will always aim at integrity, truth-seeking, pragmatism, and brand maintenance, and is committed to providing customers with high-quality products and first-class services.

Profession service: We have many years of head manufacturing and sales experience, you can act as your technical consultant, to solve your after-sales problems.

Reliable quality: Group company imported the advanced technology from Germany, Japan, Belgium and America, UK etc.

Product efficiency: Equipping with the complete automatic system, become the advanced and bigger professional manufacturer in China .

Quality promise: It has an important production scale of high-quality coils forming Stainless Steel Plate,Stainless Steel Coil.

FAQ:

Q : Can you produce from sample?

A : Yes, we can customize it according to your samples or technical drawings. We can make molds and fixtures.

Q : What's your delivery time?

A : For the stock, we can ship the goods to the port of shipment within 7 working days after receiving the deposit. As for the production period, it will take about 15 to 30 days after we receive the deposit.

Q : What’s your terms of payment?

A : 30%T/T as the upfront deposit, 70% before delivery, We will show you the photos and package before you pay the balance.