Galvanized steel pipe is galvanized on the inner and outer surfaces of steel pipes to prevent corrosion of the surrounding environment and increase the service life. Galvanized pipe can be galvanized by seamless steel pipe or welded steel pipe, and different ways of galvanizing also have different…

Seamless steel pipes are perforated by the whole round steel, and the steel pipes without welds on the surface are called seamless steel pipes.According to the cross-section shape, seamless steel pipes are divided into circular and special-shaped pipes. Special-shaped pipes have many complex shapes…

Hot-dip Galvanized steel coil are available with a pure zinc coating through the hot-dip galvanizing process,It offers the economy,strength and formability of steel combined with the corrosion resistance of zinc.Avalable Specification:Width600-1500mmThickness0.12-6.0mmCoating20-600g/M2SpangleZero…

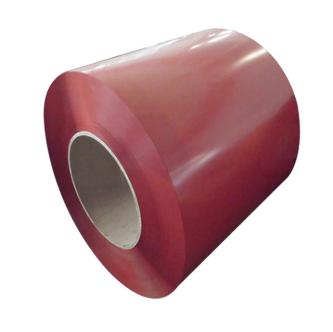

Pre-painted galvanized steel is good capable of decoration,molding,corrosion resistance. It generally displays superior workability,durability and weather resistance.Avalable SpecificationPre-painted Galvanized Steel Coil Pre-painted Aluzinc Steel Coil Width600-1500mm600-1500mmThickness0.13-2.0mm(…

May

05,2023

Shandong Kaimu International Co., Ltd. is a manufacturer and exporter located in Shandong, China. They specialize in the production and export of aluminum foil, aluminum roll, aluminum tape, PET film and other related products. The company has been in operation for over 10 years and has a solid

May

05,2023

The hot-dip galvanizing process consists of three steps: surface preparation, galvanizing, and inspection.Surface Preparation: For high quality hot-dip galvanizing, steel must be properly prepared prior to being immersed in a bath of molten zinc. During the surface preparation stage, material going

May

05,2023

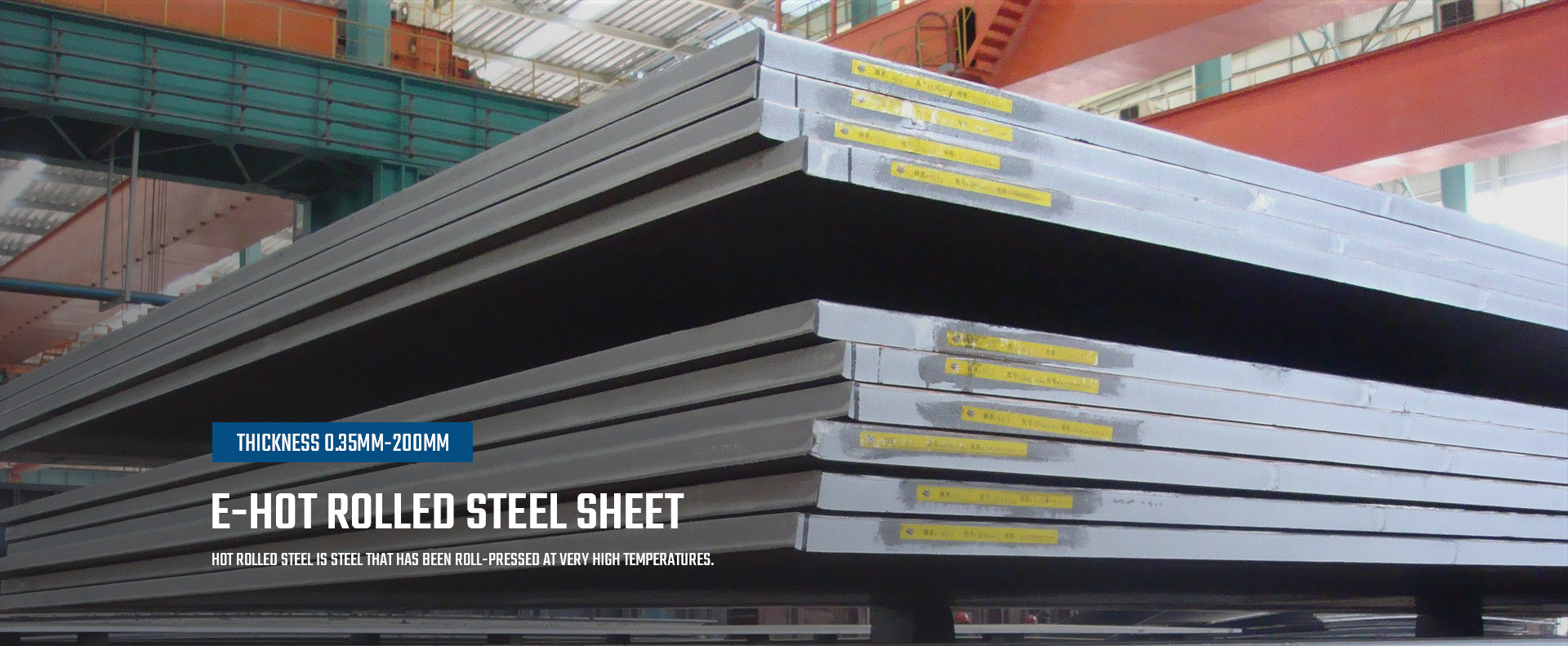

The hot rolled sheet has low hardness, easy processing and good ductility.The cold rolled sheet has high hardness and is relatively difficult to process, but is not easily deformed and has high strength.Hot-rolled sheet has relatively low strength, poor surface quality (low oxidation/smoothness),